Porous Graphene with Expanded Surface Area and Enhanced Ion Diffusion

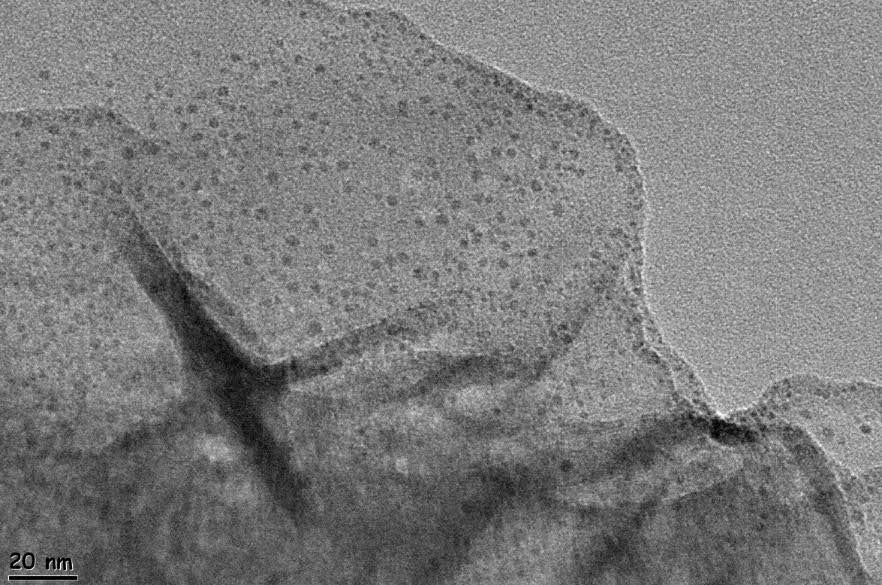

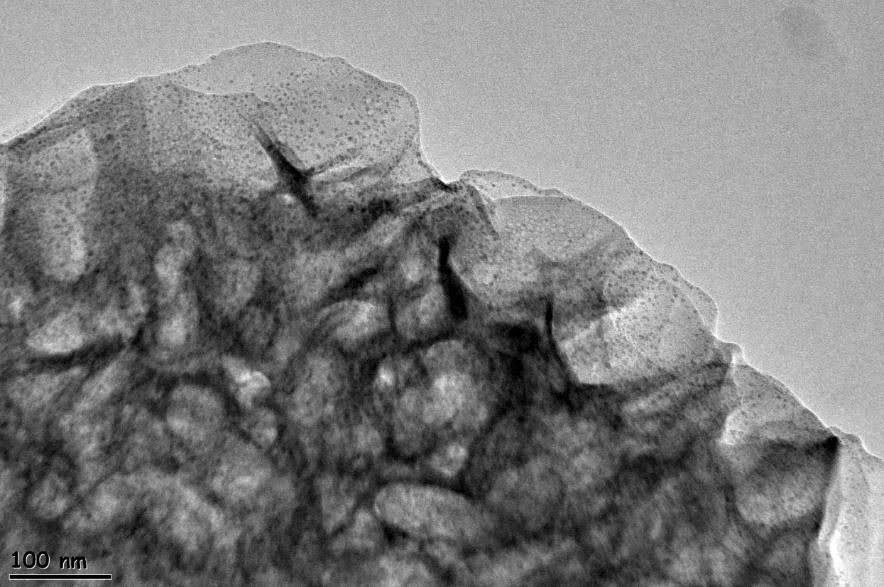

Holey Super Graphene, produced through Nanografi’s advanced manufacturing processes, is a specialized graphene derivative featuring a “holey” or porous structure. Compared to conventional graphene, it offers greater active surface area, improved ion transport, and elevated thermal conductivity, enabling next-generation solutions for battery/supercapacitor electrodes, sensor designs, conductive composites and ink formulations.

Technical Properties:

|

Sheet Resistance |

1155 ohm/sqr |

|

Electrical Conductivity |

>800 S/m |

|

Volume Resistivity |

0.11 ohm.cm |

|

Pore Size |

2 – 100 nm (can be customized) |

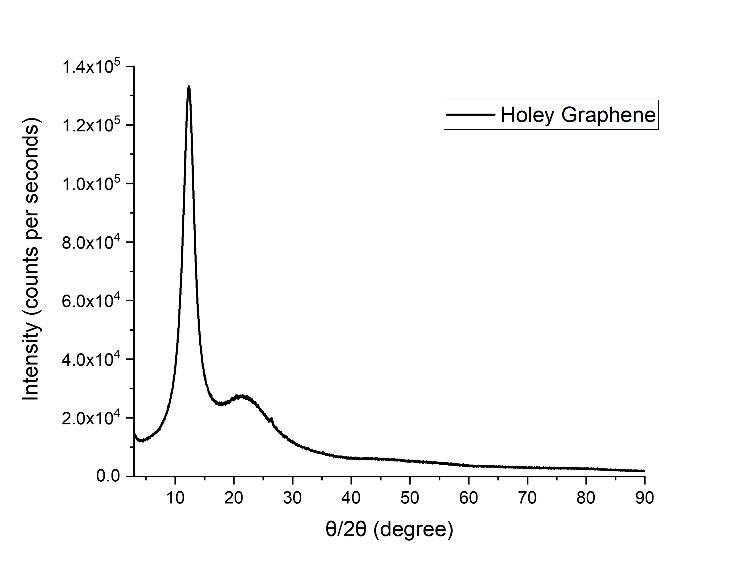

XRD Analysis of Holey Super Graphene

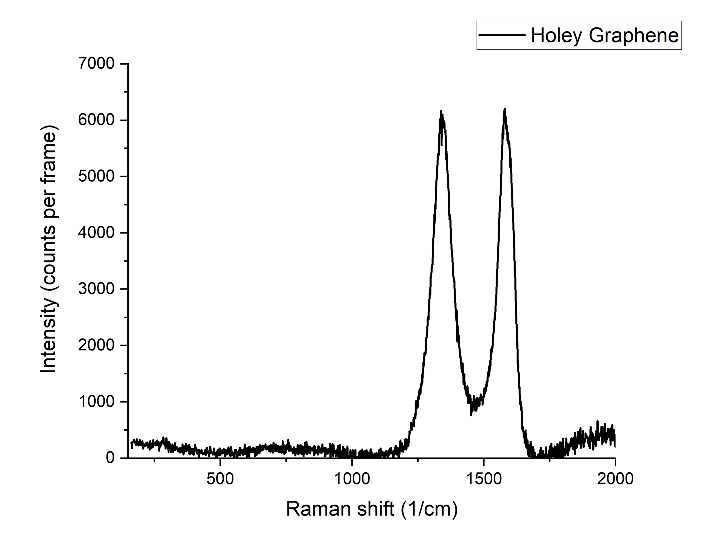

Raman Analysis of Holey Super Graphene

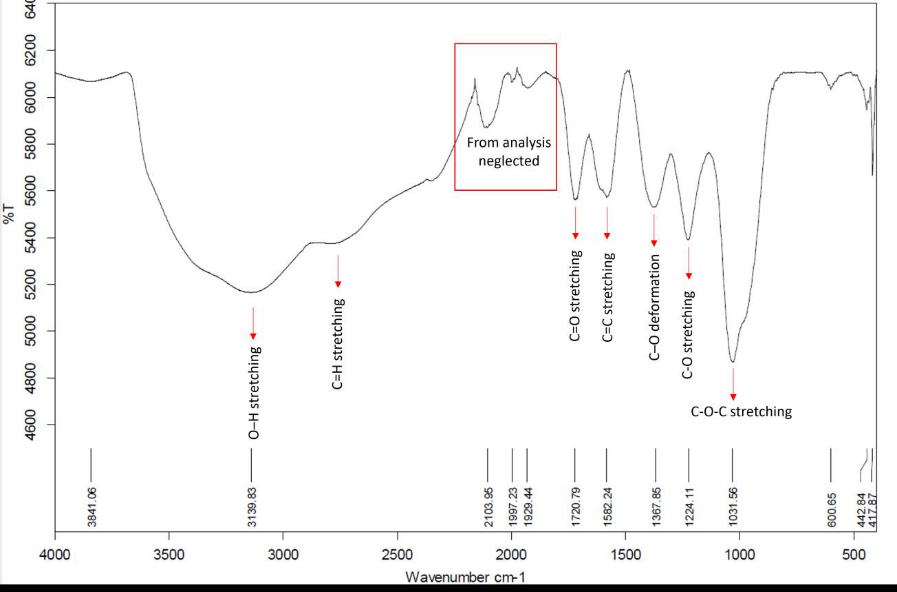

FTIR Analysis of Holey Super Graphene

Key Features

Porous (Holey) Structure for Increased Surface Area

- Nanometer-scale pores within the graphene sheets facilitate more efficient movement of ions and molecules.

Provides higher storage capacity and swift charge/discharge capabilities in battery and supercapacitor electrodes.

Boosted Ion and Electron Diffusion

- The porous framework strengthens interactions with electrolytes, yielding more efficient electrochemical reactions.

- Reduced electron transport resistance offers performance benefits for high-power requirements.

Mechanical Durability and Flexibility

- The robust graphene layers maintain stability over repeated cycles, delivering reliable long-term use.

- Its flexible, thin-film potential suits wearables, flexible circuits, and other long-life applications.

Thermal and Chemical Stability

- Maintains structural integrity in high-temperature or chemically intensive conditions, minimizing oxidation or degradation risks.

- Critical for extended operational reliability and consistency in industrial processes.

Versatile Production & Formulation

- Available in various formats—powder, dispersion, or film—to adapt to different project demands.

- Can be customized with additional conductive additives, polymer binders, or metallic components for project-specific material optimization.

APPLICATIONS